Automation Control Source

Automation Control Source

PLC Programming

HMI Development

Machine Safety

SCADA Development

PLC Programming

Although we work on industrial Process Control projects, we have chosen to specialize in multi-axis motion control for both high speed and precision applications. This is the area where even seasoned PLC programmers will usually run into trouble.

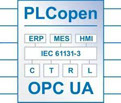

We will develop the PLC code using the 5 standardized languages published in the IEC 6-1131-3 Standard such as:

• Ladder Logic (LD)

• Structured Text (ST)

• Instruction List (IL)

• Function Block Diagram (FBD)

• Continuous Function Chart (CFC).

We have access to several different software development platforms, including:

• Automation Studio

• Codesys

• TwinCat

If you would like to see how we can assist you in solving your programming challenges, please fill out the attached Project Contact Form

HMI Development

As it has been proven to increase productivity in many industries, we develop graphically attractive and unique Human Machine Interfaces (HMI), to give machine operators the tools they need to improve their performance.

Our HMI Developments can be multilingual, and support over 250 communication drivers, allowing for a direct connection or bridging to almost any PLC or Instrumentation on the market. We also support OPC Server or Client. In Applications where several HMI’s are required, we support several Master or Slave devices.

Most of our development runtimes are supported under Win CE embedded. Only if “Active-X” or “.Net” functionality is required by the application, will we utilize XP or Win7 embedded OS.

This makes our HMI’s very customizable and cost effective solutions, either for new machine developments or control retrofits for your existing machines.

If you would like to see how we can assist you in solving your Machine Interface challenges, please fill out the attached

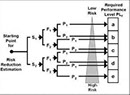

New ISO-13849-1 Safety Standard

Many Companies have only recently understood the different Category Classes within EN-954 and how to design a compliant safety circuit. Now ISO-13849-1 is confusing everybody with Performance Levels.

The ISO-13849-1 standard is not really new. A 5 year moratorium actually just ended on December 31/2012, and now it extends and supersedes EN-954. For the first, time European and American Safety Standards are the same.

ACS can help you through the proper “risk assessment” of new or your existing equipment retrofits, as well as the design of proper and compliant safety circuits, as well as the required calculations, documentation, and test procedures.

If you would like to see how we can assist you in solving your Machine Safety challenges, please fill out the attached Project Contact Form

SCADA (Supervisory Control and Data Acquisition)

Automation Control Source (ACS) provides SCADA design and development services for projects of any size. ACS also offers cost-efficient SCADA as a service, on our AWS co-located SCADA and Database Servers. Start small, but always be prepared for future growth, as we are capable of allocating up to 10,000,000 Tags per SCADA Server.

Our remote terminal unit (RTU) will seamlessly integrate into your existing control infrastructure, as it supports over 200 different communication drivers as well as all standardized protocols. All RTU’s are shipped out pre-configured, with the required SCADA client services, and offer secure and redundant communications to our servers; all independent of your business network.

This minimizes capital expense, shortens the commissioning of your SCADA system to days, rather than months, and you’ll never have to worry about maintaining your SCADA system

If you would like to see how we can assist you in solving your data acquisition challenges, please fill out the attached